Laying GRF System with synthetic grass

The GRF System raised flooring system is particularly suitable for the application of the final covering with synthtic grass. With this system, you can achieve a walkable surface that closely resembles the grass of a green lawn, allowing you to create a garden, a green area combined with ceramic tiles, a terrace, or even a full-fledged "green roof".

The advantages of this system are numerous:

- The aesthetic appeal of a real green lawn;

- Quick and sample installation process;

- "Dry" system without the use of adhesives or chemicals;

- Perfectly level surface;

- Water-drainage system, preventing water stagnation;

- Can be installed on various types of subfloors, whether waterproof of draining;

- Minimal to no maintenance required;

- Water and energy savings compared to natural grass lawns;

- All system components are recyclable;

- Wide range of accessories available for a flawless finish, such as vertical closures and perimeter spacers.

Guide to laying GRF System with synthetic grass

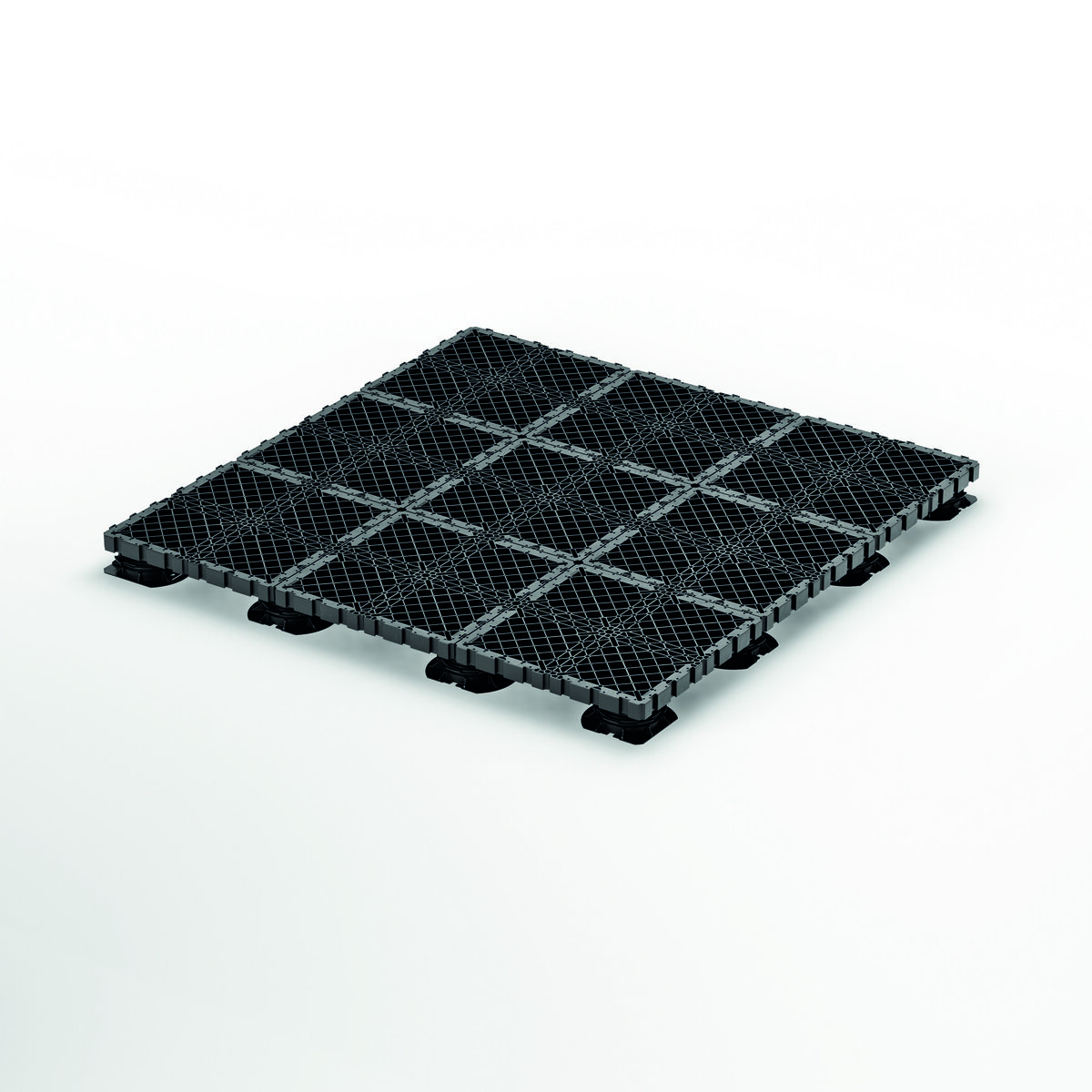

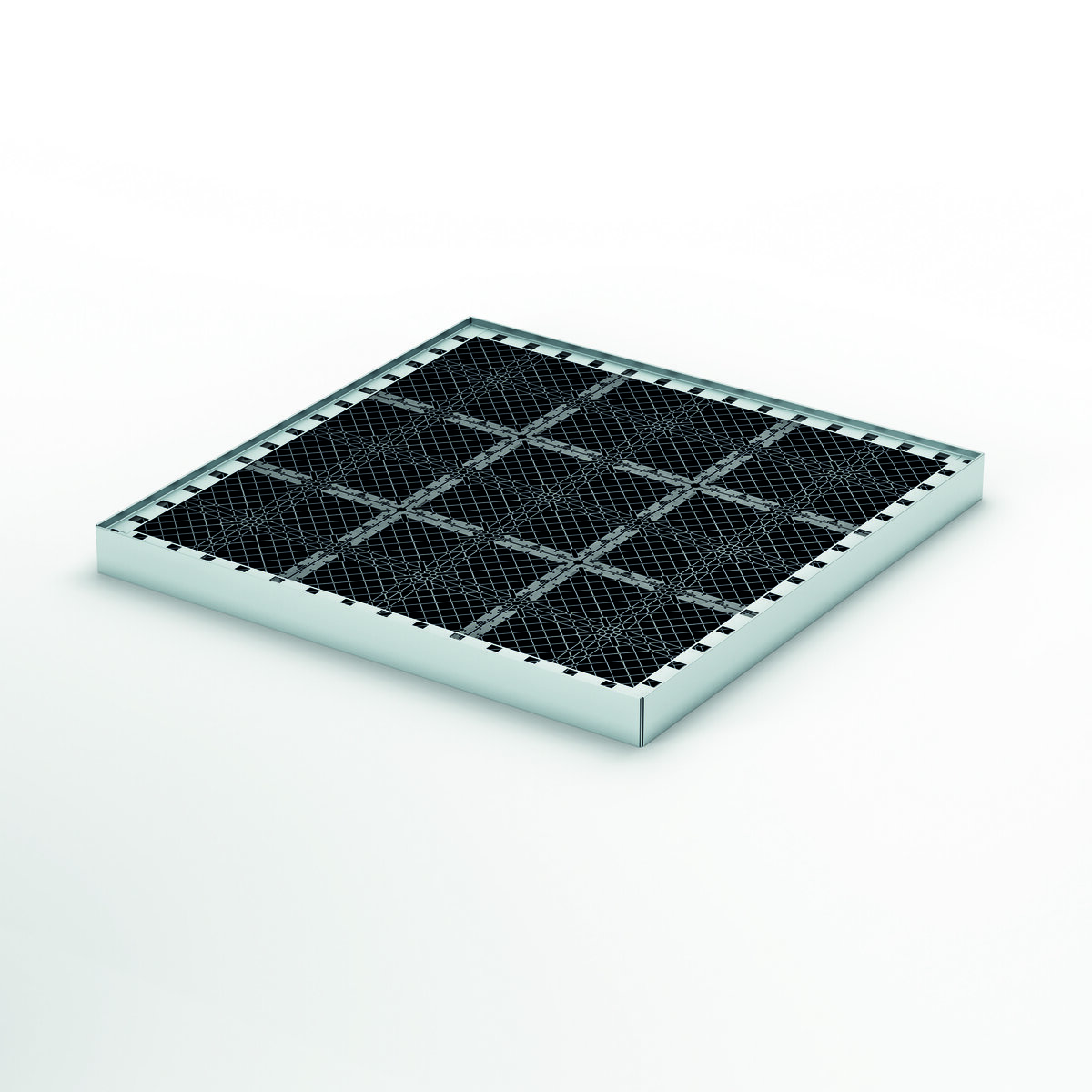

1. THE SUBSTRUCTURE

The substructure of the GRF System consists of height-adjustable supports and grids.

Once the desired height of the system is determined, you can choose the type of support. The minimum number of supports per square meter is 4, and the number of grids per square meter is also 4.

2. THE VERTICAL INFILL

If the system does not have a wall support or any containment, you can use the "vertical perimeter profile" for vertical sealing.

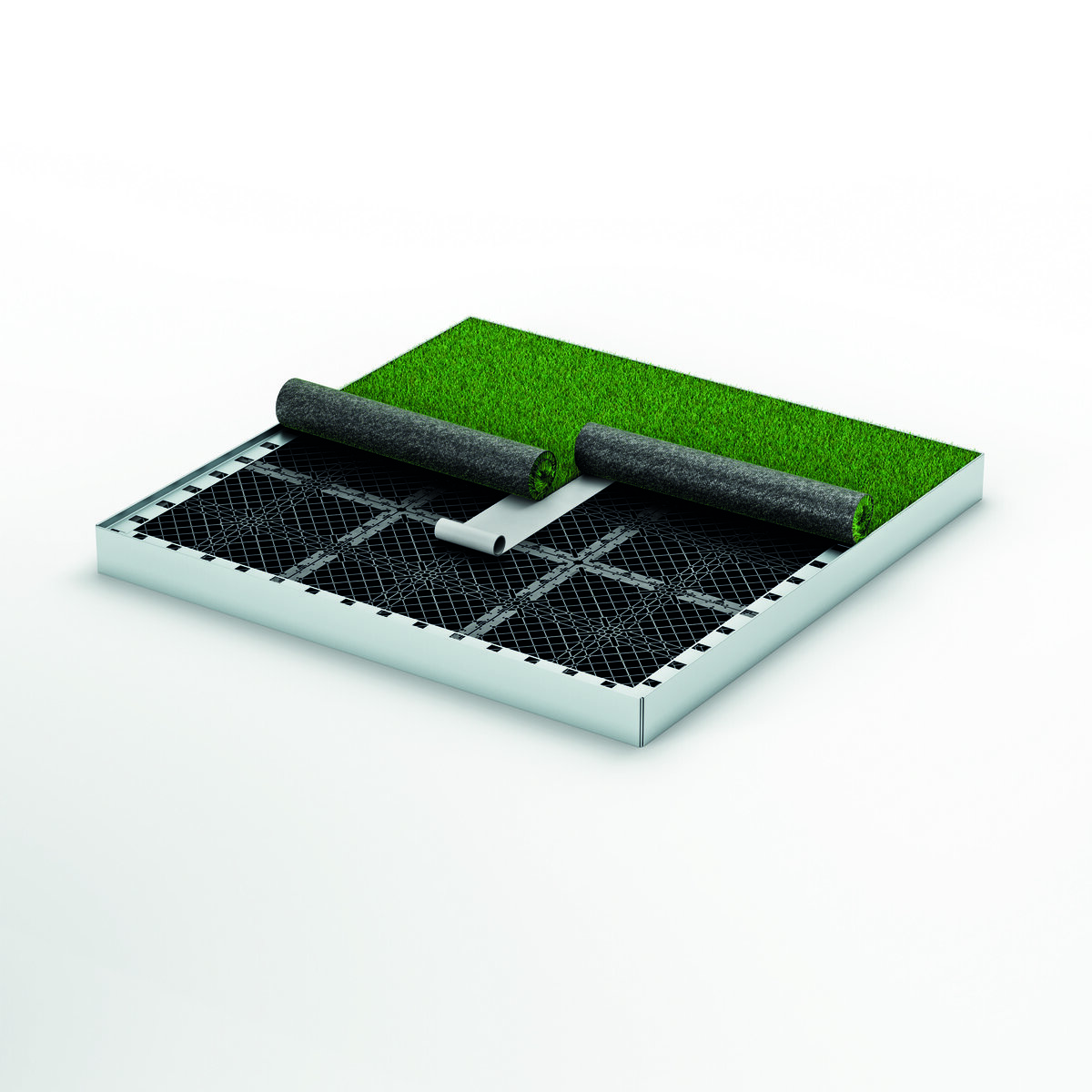

3. SYNTHETIC GRASS

The synthetic grass covering is done by unrolling the rolls of grass. Once aligned and laid out, they are joined together using an adhesive joining tape, which is inserted underneath the edges that need to be joined.

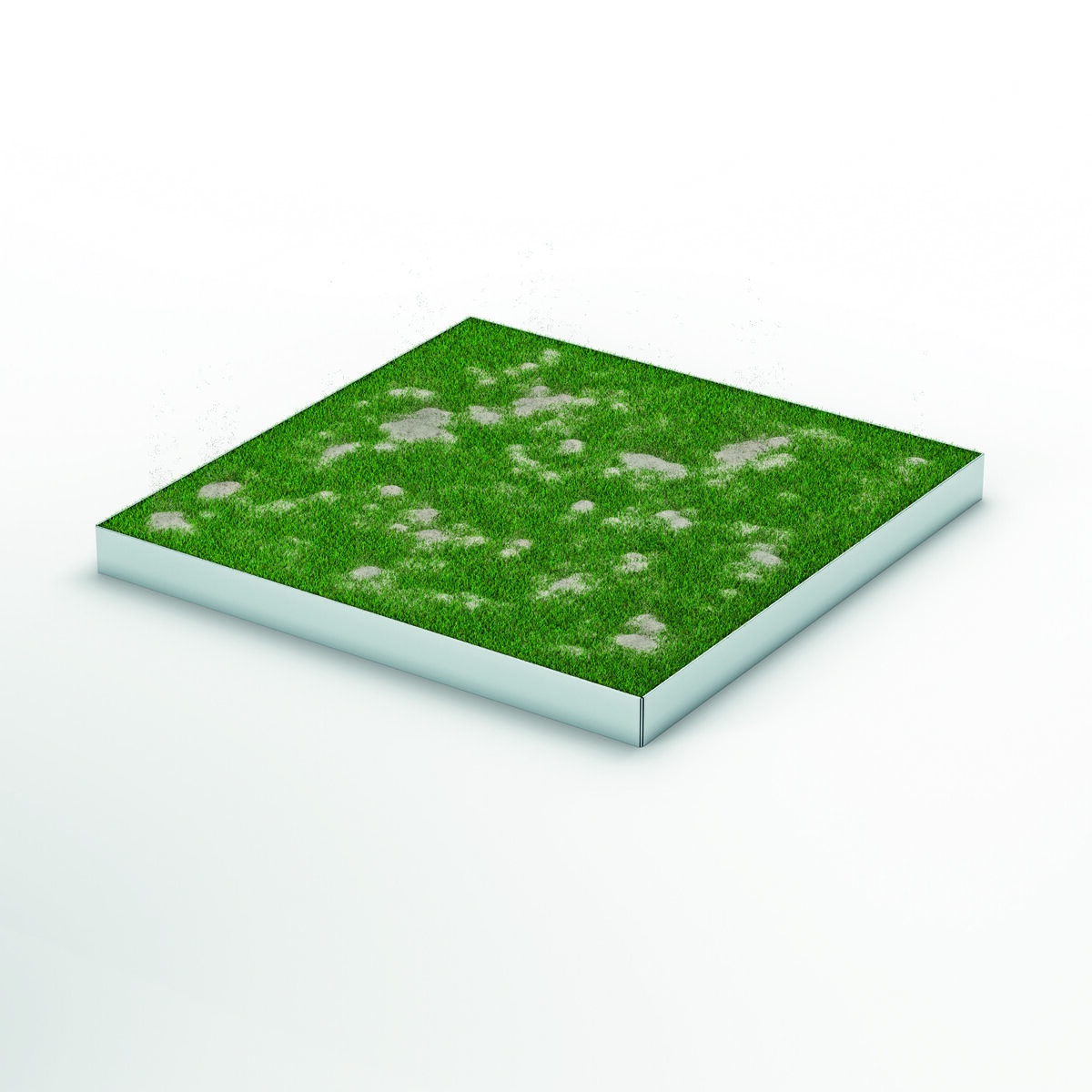

4. CLOGGING WITH SAND

The final step is infillingwith sand, which serves to stabilize the grass and provide weight. The sand should be evenly spread, typicalli at a rate of 4 to 5 kg per square meter.